Selecting a bga heatsink is a key step for engineers who work with compact electronic packages, especially in devices where temperature control affects long-term reliability. At the beginning of a project, design teams often evaluate thermal resistance, component spacing, and overall system loading to determine what type of heatsink structure is appropriate. Companies such as Dingmetal communicate frequently with procurement teams and thermal engineers who want clear guidance on how various design choices influence real-world performance. Because bga heatsinks must operate in areas with very limited PCB surface area, engineers prioritize predictable thermal behavior. They need solutions that maintain stable temperatures during continuous workloads while avoiding stress on the BGA package. This is why selecting a suitable heatsink becomes an essential part of the initial thermal planning process for any compact hardware system.

Material Characteristics and Their Role in Thermal Behavior

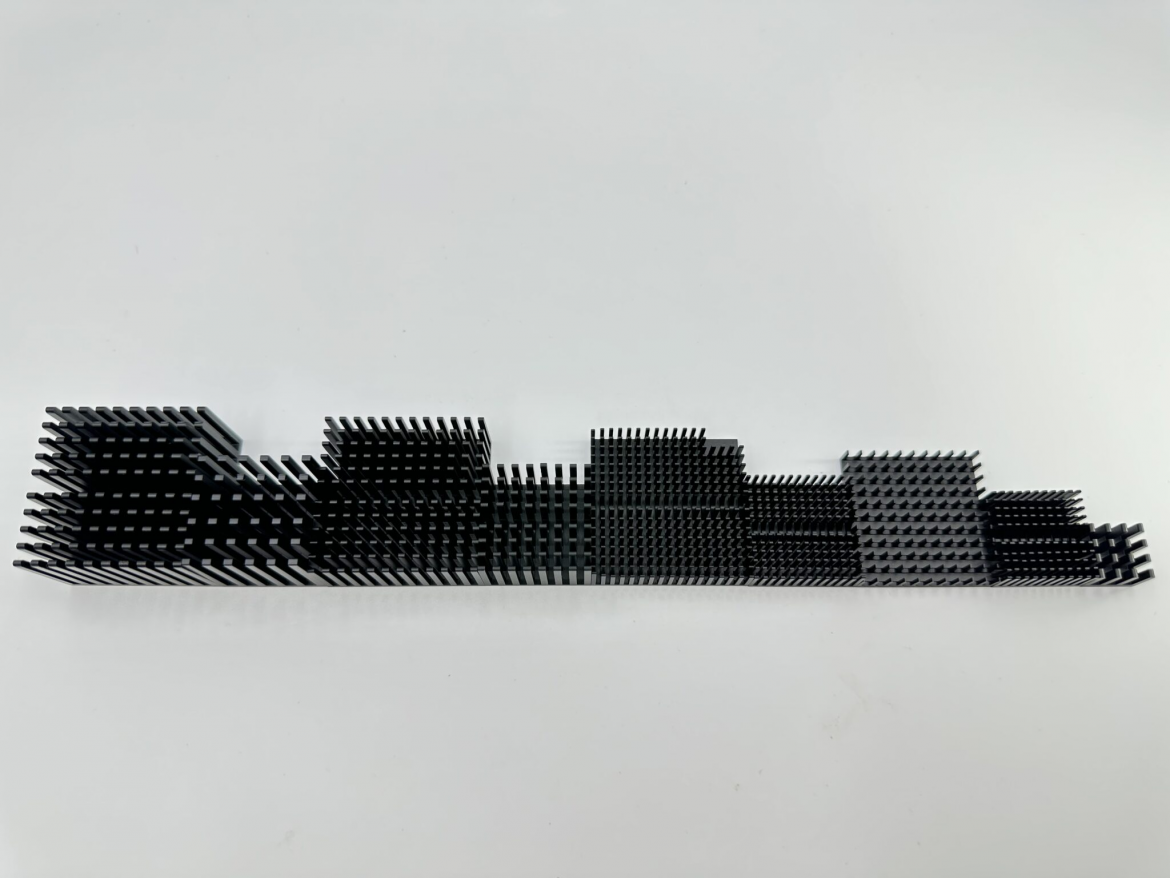

When comparing different bga heatsink options, material selection becomes a foundational factor. Copper is widely used for heat-spreading applications that require quick removal of localized heat. Aluminum, however, remains popular due to its balance of weight, machinability, and consistent thermal behavior across normal operating ranges. Engineering teams usually examine how conductivity, surface treatment, and production precision influence the final thermal path. Because small differences in surface flatness or machining tolerance can affect the heat transfer interface, they seek suppliers capable of maintaining stable production control. Dingmetal supports these material evaluations by providing components with reliable quality and uniformity, helping designers match performance targets with real manufacturing capabilities. With properly selected materials, bga heatsinks can maintain predictable thermal resistance across different environmental conditions and duty cycles. This ensures that the thermal path remains stable even when the package operates under fluctuating workloads.

How Mounting Methods Influence Structural and Thermal Stability

Mounting methods significantly affect how a bga heatsink performs and how well it fits into a dense PCB layout. Adhesive mounting is commonly preferred in tight spaces where mechanical fixtures cannot be used. It provides secure attachment without increasing the vertical profile. For projects that require maintenance access or mechanical stability under vibration, clip-based or pin-based mounting provides more consistent pressure distribution across the package surface. Engineers evaluate the mechanical stress, board flexibility, and thermal interface uniformity before choosing a method. Dingmetal, with experience in mechanical hardware and thermal module production, often assists teams by offering practical insight into how each mounting approach interacts with different BGA structures. Additionally, engineers consider the compact footprint found in many bga heatsinks, which allows them to fit within densely populated boards without interfering with nearby components. This small form factor ensures that thermal improvements do not compromise layout flexibility during product development.

Conclusion: Matching Thermal Needs with Appropriate BGA Heatsink Choices

Choosing a bga heatsink becomes more manageable when material behavior, installation requirements, and thermal limits are evaluated together. Teams can analyze how conductivity, mounting stability, and system airflow influence overall cooling performance. Suppliers such as Dingmetal contribute by offering dependable production quality, responsive engineering support, and manufacturing consistency that aligns with project timelines. Their guidance helps ensure that bga heatsinks integrate smoothly into compact assemblies and maintain the required heat dissipation capability throughout the device’s operating life. By combining accurate thermal evaluation with suitable material and mounting selections, engineering teams achieve a solution that supports both immediate project needs and long-term functional stability.