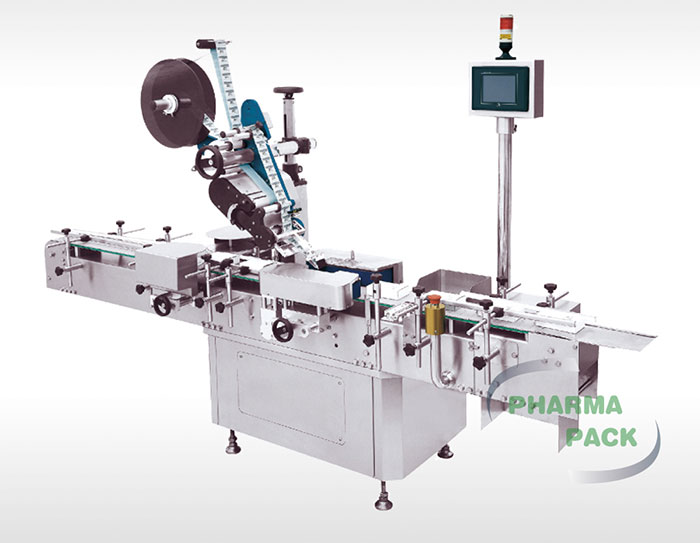

Pharmapack offers advanced solutions for experienced pharmaceutical professionals who require precision and reliability in labeling operations. As a trusted labeling machine manufacturer, they design pharmaceutical labeling equipment that combines accuracy, efficiency, and user-friendly operation. Their LFLB-4120 flat labeling machine exemplifies their commitment to high-quality performance, ensuring that production lines maintain consistent labeling standards across various product types. Experienced users rely on Pharmapack to provide equipment that enhances workflow without compromising quality.

Accurate Labeling with Smart Sensors

Pharmapack’s pharmaceutical labeling equipment, including the LFLB-4120, incorporates advanced object-detecting and label sensors. These sensors operate without interference from external light, ultrasonic signals, or other disruptive sources, ensuring precise labeling during continuous operation. Experienced professionals benefit from the machine’s ability to maintain accurate label placement even when handling different types of containers. As a leading labeling machine manufacturer, Pharmapack prioritizes sensor reliability to reduce errors and minimize downtime, which is crucial for high-volume production environments.

Flexible Label Management

The LFLB-4120 features an intelligent label management function that automatically counts used labels and displays remaining label quantities on the operation interface. This feature enables operators to monitor label usage in real time, preventing production interruptions caused by label shortages. In addition, the adjustable photo-sensitivity of the label sensor allows the machine to adapt to labels of varying transmissivity without requiring sensor repositioning. Pharmapack’s pharmaceutical labeling equipment ensures that experienced users can switch between different label types efficiently, supporting continuous and reliable production.

Safety and Efficiency Enhancements

Another key characteristic of Pharmapack’s pharmaceutical labeling equipment is its proactive detection system. The LFLB-4120 identifies when a label roll is depleted, ensuring that the next label is correctly applied and avoiding omissions. If the label roll is used up, the machine automatically stops, preventing production errors and reducing waste. As a labeling machine manufacturer, Pharmapack integrates these safety and efficiency features to support experienced operators in maintaining smooth, high-quality labeling operations without constant monitoring.

In conclusion, Pharmapack’s pharmaceutical labeling equipment combines smart sensor technology, flexible label management, and reliable safety features to provide high-performance solutions for experienced professionals. Their LFLB-4120 flat labeling machine exemplifies the precision, efficiency, and adaptability expected from a leading labeling machine manufacturer, making Pharmapack a trusted partner for advanced pharmaceutical labeling operations.