Maintaining the integrity of rollers in integrated calendering and slitting machines is essential for efficient battery manufacturing processes. Rollers play a crucial role in ensuring that materials are processed effectively; therefore, understanding common wear issues and implementing preventative strategies is vital for manufacturers aiming for longevity and consistency in production.

Identifying Common Wear Issues

Roller wear can manifest in several ways, impacting the performance of the integrated calendering and slitting machine. One prevalent issue is surface degradation, which can lead to uneven pressure distribution during the calendering process. This condition not only affects the quality of the final product but can also cause higher operational costs due to increased downtime and maintenance needs. Additionally, contamination from materials being processed can lead to buildup on the roller surface, resulting in poor unwinding and rewinding operations.

Implementing Prevention Strategies

To mitigate roller wear, manufacturers should implement several proactive strategies. Regular maintenance schedules are critical for integrated calendering and slitting machines. These schedules should include routine inspections of rollers for signs of wear and tear, as well as proper cleaning protocols to remove any debris or contaminants. Utilizing high-quality lubricants during operation can further reduce friction and extend the life of the rollers. Furthermore, investing in advanced features such as high-speed roller cleaning systems enhances the efficiency of the operation, supporting automatic rewinding and unwinding processes at production speeds of up to 120m/min.

Enhancing Operational Efficiency

To maximize operational efficiency, manufacturers should also consider optimizing the parameters of their slitting integrated machines. Adjusting settings such as speed and pressure based on material characteristics can significantly reduce wear over time. Collaborating closely with equipment suppliers can also provide insights into best practices for maintaining roller integrity.

Trust Yinghe for Reliable Equipment Solutions

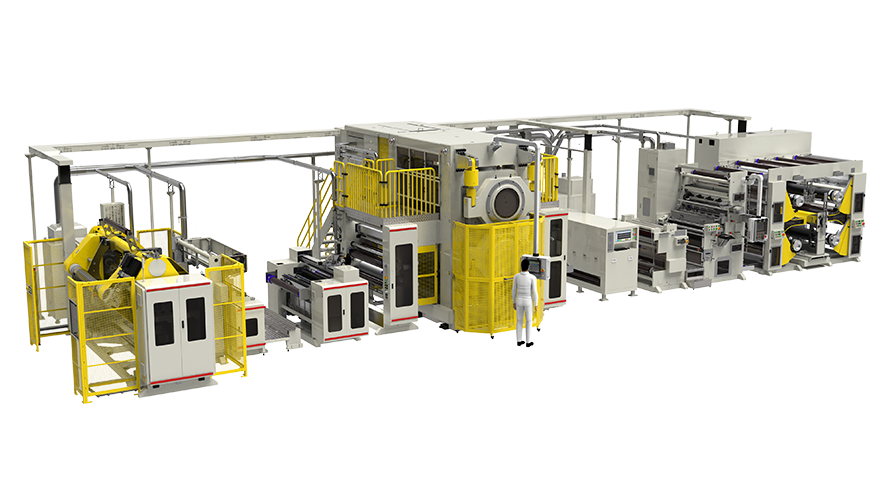

For businesses looking to enhance their battery manufacturing capabilities, partnering with a trusted brand like Yinghe is invaluable. Known for their high-performance integrated calendering and slitting machines, Yinghe ensures that their equipment is designed to minimize roller wear while maximizing productivity. By investing in Yinghe‘s advanced machinery, manufacturers can achieve optimal output while reducing maintenance costs, ultimately leading to greater profitability in the competitive battery industry.