Cosmos Press provides advanced solutions for abrasive tool production, with their automated hydraulic press for resin grinding wheel production offering consistent performance across multiple production stages. Designed to support both precision and automation, their system integrates essential units such as pre-pressing, hot-pressing, demoulding, and mold conditioning. By automating each step, this system improves output, reduces manual error, and ensures uniform product quality.

Integrated Functions for Streamlined Production

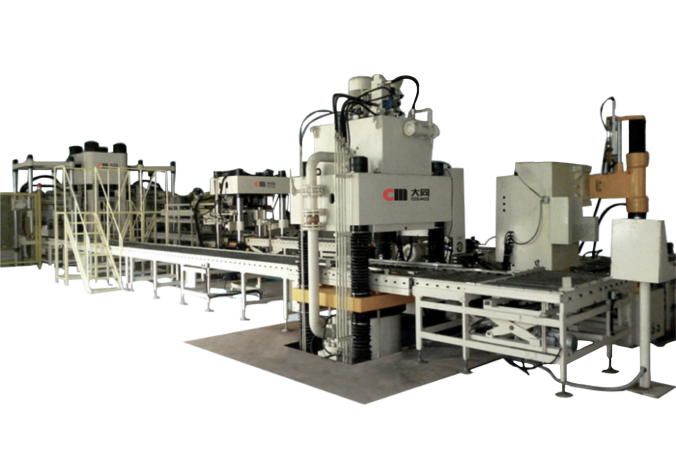

Their automatic production line for resin grinding wheel production includes a range of coordinated units such as the packing hydraulic press, pre-press hydraulic press, and dual hot-press machines. These work together to shape and finalize resin grinding wheels with consistent pressure and temperature control. A demoulding press allows easy removal of finished parts, while thermal insulation boxes and mold cooling devices help maintain ideal operating conditions. This combination ensures efficient heat transfer and stable performance across production cycles.

User-Friendly Operation and Adaptability

Ease of use is a major feature of this automated hydraulic press for resin grinding wheel production. With a modern human-machine interface, operators can adjust, monitor, and save process settings quickly. The system is not only designed for resin grinding wheels but is also adaptable to other abrasive product manufacturing needs. It suits operations where precise pressing and shaping are critical to product quality.

Conclusion: A Reliable System for Precision Manufacturing

By offering a complete automatic production line for resin grinding wheel production, Cosmos Press enables manufacturers to increase productivity while maintaining consistent product standards. Their system supports high-volume output with minimal manual intervention, making it a dependable solution for companies focused on efficient, high-quality abrasive tool manufacturing.